Stretch Wrap Machines & Secondary Packaging Equipment from Semi-automatic to automatic. OZ Packaging is authorized partner with Robopac and offer their full line of products. Don't see your solution below? Contact us to learn more.

ROBOT S7

The Robot S7 is a new range of self-propelled semi-automatic packaging machines. The Robot S7 portable stretch wrap machine includes the latest advanced technologies, the utmost attention to safety systems, a high level of packaging autonomy, and great work flexibility. This machine is built to wrap and stabilize palletized loads of any shape, size and weight, using stretch film.

ECOPLAT

The Ecoplat semi-automatic turntable stretch wrapping machines wrap up to 25 loads per hour. This turntable shrink wrap machine is R-connect ready, which allows you to monitor and improve your packaging performance through remote assistance.

• Structural Integrity – 65” turntable with 28 support

bearings. • Maximum weight: 4400 lbs. • Standard wrap height: 86” (110” available) • Unique record-a-wrap feature to record wrap

pattern. Start, stop, jog up, jog down are all

recorded. Up to 20 movements. • Film tension braking system spreads force out

evenly over a larger surface area resulting in a

much smoother film delivery. No “jerking”

movements that break the film. • Control Panel: FRD

MASTERPLAT

The Masterplat is designed for customers wrapping up to 30 loads per hour. It comes with productivity improving standards like a Self-Learning Wrap Program and a heavy duty 4,400 pound capacity turntable.

• Structural Integrity – 65” turntable with 28

support bearings. • Maximum weight: 4400 lbs. • Standard wrap height: 86” (110” available)

ROTOPLAT 708

The Rotoplat 708 with CUBE Technology is the most innovative semi-automatic stretch wrapper in the market. It is also the easiest to use, thanks to its intuitive seven (7) inch color touchscreen. The Rotoplat 708’s patented roll carriage design combined with the ultimate flexibility of CUBE Technology allows you to wrap any load with any film with complete confidence. The Multi-Level Variable Containment is optimized at each level. Containment force is adjustable up to nine (9) times on each load. CUBE Technology will reduce your film usage by 30% – 55% and potential product damage up to 40%. This ensures that your product reaches your customer in “as-made” condition by maintaining proper wrapping standards.

TECHNOPLAT 708

The Technoplat 708 CS (Clamp, cutting and sealing unit) or CW (cut and weld) semi-automatic turntable stretch wrapping machine cuts and attaches the film tail to the load at the end of the wrap cycle for superior load containment. The Technoplat 708 CS/CW semi-automatic shrink wrapper saves 2 minutes of labor per load by keeping the operator on the fork truck. For the average customer, this translates to labor savings of $29,000 over 5 years and $60,000 over the life of the machine! Our Remote Control start allows the fork truck operator to start the wrap cycle while staying on the fork truck. This allows them to leave the current load to pick up and stage another load which improves productivity.

ROTARY 708

Rotary arm stretch wrappers are ideal for wrapping heavy and unstable loads. The Rotary 708 with CUBE Technology is the most innovative rotary arm stretch wrapper on the market. It is also the easiest to use, thanks to its intuitive seven (7) inch color touchscreen. The Rotary 708 with CUBE Technology will reduce your film usage by 30% to 55%, improve your load containment and reduce potential product damage. This ensures that your product reaches your customer in “as-made” condition by maintaining proper wrapping standards.

ROTOTECH 708 CS

Perfect for heavy and unstable loads. Save time and increase productivity with the automatic cut, clamp and spreading system (CS) which keeps your operator on the fork truck. The Rototech 708 CS stretch wrapper with CUBE Technology will reduce your film usage by 30% to 55%, improve your load containment and reduce potential product damage. This ensures that your product reaches your customer in “as-made” condition by maintaining proper wrapping standards.

TECHNOPLAT 708 CW

Our Rototech CW semi-automatic stretch wrapper with CUBE Technology will reduce your film usage by 30% to 55%, improve your load containment and reduce potential product damage. This ensures that your product reaches your customer in “as-made” condition by maintaining proper wrapping standards. The Heavy Duty Cut, Clamp and Weld System can save you an average of two (2) minutes of labor per load. For the average customer, this translates to $60,000 in labor savings! Our PVS roll carriage employs a dual motor pre-stretch system that provides the ability to pre-stretch film from 150% up to 400% using two independent, variable AC motors.

COMPACTA

Designed specifically to wrap motorcycle, ATV, go kart and lawnmower tires up to 33″ in diameter, the Compacta Tire stretch wrap turntable eliminates expensive and time-consuming corrugated packaging. Innovative features including vertical power guides to position and rotate tires during wrapping; and a color touchscreen control panel capable of running pre-set programs set the standard in tire wrapping. Safe, simple operation includes automatic film clamping, cutting, and heat-sealing unit. All Compactas feature constant film tensioning to improve package integrity and reduce film breaks.

ORBIT R HORIZONTAL

Our Orbit R horizontal stretch wrapper line provides high-speed and high-performance and can be added to existing work cells or integrated lines. The Orbit R is a rotating ring machine for spiral wrapping elongated products. The machine is equipped with electro-welded mesh safety guards to protect the operator during operation. Infeed and outfeed units automatically adjust to ensure proper stabilization of the product. The length of the run can be adjusted manually, if needed, to compensate for products of varying height. Plus, the highly reliable, dual rod cut and clamp system fully automates the wrapping process.

RT AUTOMATIC

At 17 RPM, this low to medium volume made in the USA automatic stretch wrapper sets the standard for speed and efficiency in its category. Keeping our customers safe is priority one at Robopac. Category 3 level safety is included with the new RT Automatic. Category 3 is designed so that a single fault in any of its parts does not lead to the loss of a safety function. For the ultimate in safety, Rolling Safety Doors™ keep the operator safe by completely closing off entrance to the wrapping area on both sides of the load. This prevents the operator from accidentally entering the wrap zone which can cause serious injury. Safety Guard™ detects any obstruction at the bottom of the Rolling Safety Doors that may keep the doors from completely closing. This prevents the wrap cycle from initiating which ensures supreme safety performance. This safety platform replaces costly fencing which also saves valuable space within a facility. With one of the smallest footprints in its category at 123” deep x 198” wide (169 sq. ft.), the RT Automatic saves valuable floor space for the food, beverage, and other industries where floor space is extremely valuable. With 250% standard pre-stretch included, the RT Automatic guarantees that stretch film will go further which saves money. Depending upon the operations throughput, an ROI can be calculated demonstrating film savings and payback period for the machine.

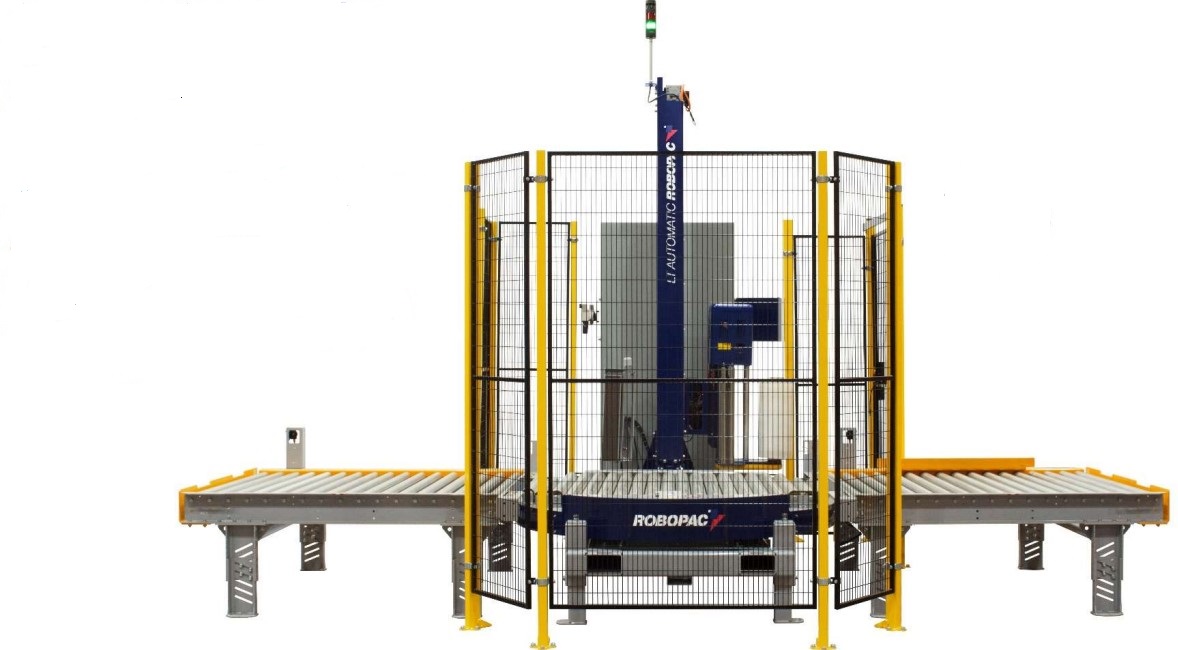

LT Automatic

Entry level automation with high level features. At 17 RPM, this low to medium volume made in the USA automatic stretch wrapper enables your operation to wrap faster, uses less space and film, and keeps your operators safe. The end result is increased performance. Automatically senses top of load to provide your load with full film coverage. Cut, clamp, and wipe down unit secures the film tail at the end of the wrap cycle to the load to avoid loss of containment at the bottom of the load.

SMALL FOOPRINT

With one of the smallest

footprints in its category, the LT

Automatic is able to be placed in

areas that meet your operations

workflow requirements