Mekitec

We provide food manufactures with compact, easy to use, Mekitec X-Ray inspection systems that provide excellent performance and the best value in the industry.

Uncompromising Accuracy

Mekitec X-ray machines offer exceptional detection capabilities, ensuring even the tiniest imperfections or foreign objects are swiftly identified, leaving no room for compromise on product safety and quality.

Streamlined Efficiency

With Mekitec, optimize your production line by seamlessly integrating our X-ray systems. Enhance efficiency, reduce waste, and boost productivity while maintaining superior standards throughout the entire process.

Tailored Solutions

We understand that every industry and application is unique. That's why Mekitec offers customizable solutions to meet your specific requirements.

Future-Proof Technology

Stay ahead of the game with Mekitec's forward-thinking technology. Our X-ray machines are built to adapt and evolve, ensuring long-term value and compatibility with emerging industry standards.

MEKI ONE

MEKI™ ONE is a concept with all you need from a Critical Control Point in one compact package. The ONE concept combines the superior X-ray sensitivity with the smallest footprint, still having all the latest features and functionalities expected by the global quality standards, such as integrated automatic reject, rejection bin, confirmation sensors, and system reporting.

MEKI™ ONE makes it easy for food producers to introduce food X-ray quality control to any packaging lines. The concept ensures that

producers will meet and exceed expectations for production quality.

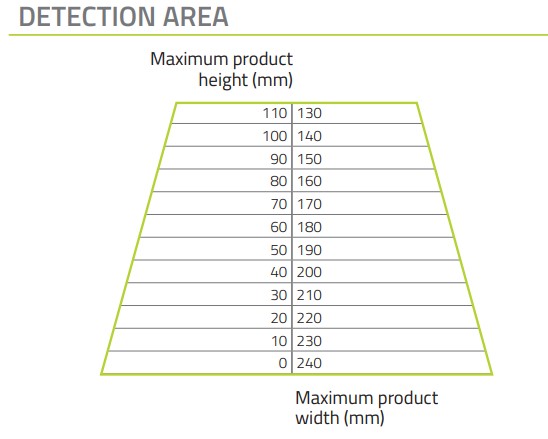

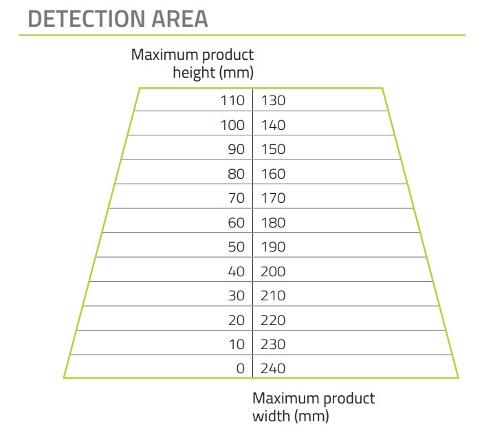

MEKI

This Meki is especially designed for the inspection of medium-sized products and trays of smaller products. As like with other Mekitec X-ray systems, high moisture, salt content, or different type of packaging materials (e.g. metal or aluminum) are not a problem for the inspection.

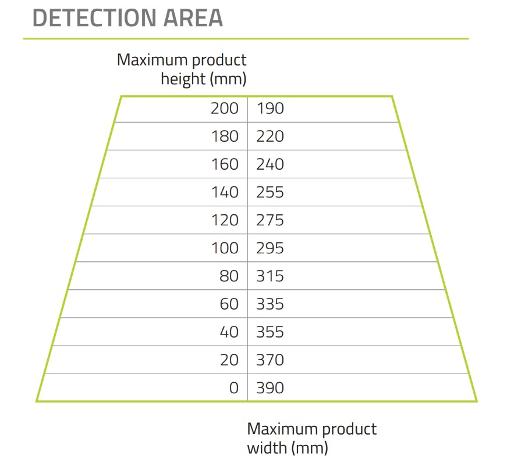

MIDMEKI

This Meki is especially designed for the inspection of medium-sized products and trays of smaller products. As like with other Mekitec X-ray systems, high moisture, salt content, or different type of packaging materials (e.g. metal or aluminum) are not a problem for the inspection.

SIDEMEKI

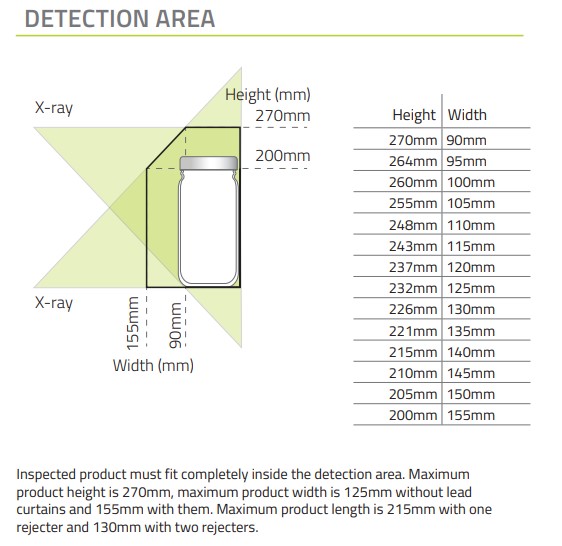

The SIDEMEKI™ system is designed for production lines where the food is in packages that are taller than wider, such as bottles, cartons, containers and cans. Ensuring smooth production flow is essential with these packaging types, setting a higher expectation for the design of the inspection equipment.

SIDEMEKI™ is the only quality control solution offering food producers a choice to select one or two X-ray generators based on the exact need for the product inspection. With tall products, this means that the system always has the needed inspection accuracy necessary for foreign object detection and specific quality functions, e.g. fill level and cap inspection. This equals the best value in the industry.

Key Application

Counter & Filling Inspection

Confirm every pack has the right number of pieces and fillings, even when pieces overlap

How it Works

Set the expected piece count and filling targets. The X-ray image is analyzed to find pieces and filling areas; the system measures density in each area and estimates how many pieces belong to it. Smart separation tools split touching or horizontally joined pieces, then results are checked against limits for pass or reject. Auto-calibration keeps performance stable, similar to Foreign Object Detection.

Key Benefits

- Accurate counts and filling verification, even with overlapping pieces

- Fewer complaints and giveaways by rejecting only off-count packs

- Consistent quality that protects brand trust

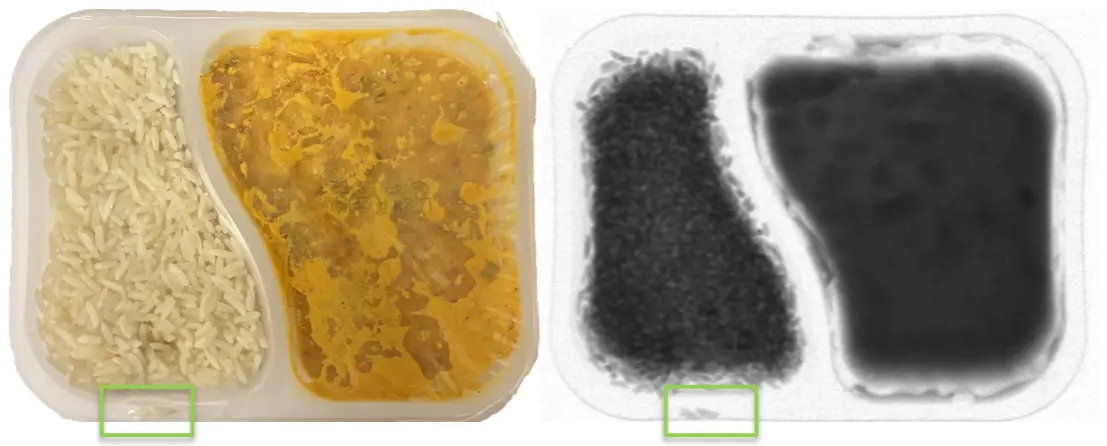

FO Detection in High-Density Containers

Detect foreign objects in hard-to-reach areas within high-density containers

How it Works

MEKI AI makes it possible to detect foreign objects even in challenging, dense products or packaging. By adapting how the system inspects different areas, it significantly improves detection accuracy where it's traditionally most difficult. The capability is most useful for SIDEMEKI applications.

Key Benefits

- Improved detection in challenging high-density containers

- Improved detection in challenging areas

- Clear visual segmentation

- Tailored algorithm selection

Seal Inspection

Prevent food or product spoilage by rejecting products with faulty seals

How it Works

The system detects broken or open seals by scanning the sealed area of each package. It flags seals that trap product material, often a sign of leakage or contamination. It works reliably across all packaging types and sealing methods.

Key Benefits

- Ensures seal integrity

- Prevents leaks and spoilage

- Adapts to all product shapes and sizes

Glass detection in glass containers

Detect foreign objects especially glass within a glass container

How it Works

The glass container is divided into multiple zones, e.g. high- and low-density zones. Users customize detection settings specifically for glass detection, leveraging both classic imaging techniques and advanced AI models. Configuration options and color overlays enable detection within different density areas.

Key Benefits

- Improved detection in hard-to-see zones

- Clear, color-coded visual segmentation

- Size of foreign object detection starts from 2mm for Glass contaminant in a Glass container