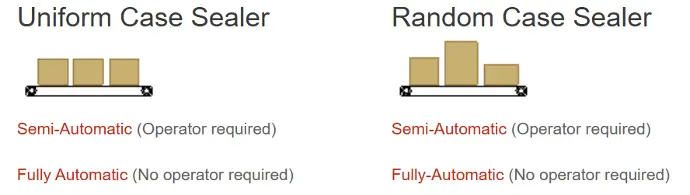

Case Sealers/Box Tapers

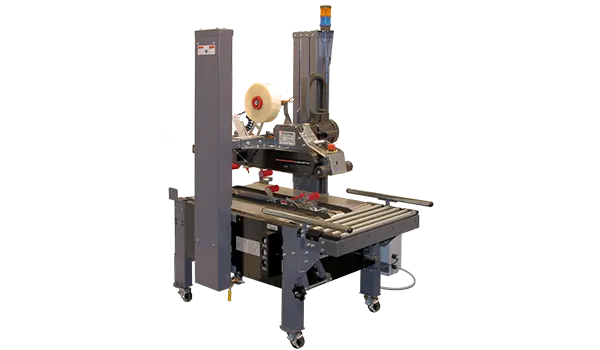

LD-7 Uniform Semi-Auto

The LD-7 case sealer is an economical solution for businesses requiring a top and bottom case taper. This machine is built to handle large runs of uniform cases or those applications that require infrequent case size changes and a small footprint. Ideal for those seeking an alternative to expensive labor costs, the LD-7 also replaces the tedious task of hand taping cases and the use of unsafe machinery. This model requires very low maintenance, minimal operator training, and operates with simple hand tightening adjustments.

Key Features:

- Economical Solution

- Economically replaces the tedious task of hand taping cases.

- Simplifies Maintenance

- Self-centering, self-tensioning belt systems save operator time (no manual adjustments required).

- Production Versatility

- Expansive case range:

- Length: 14 mm (4-1/2 in) - infinite

- Width: 14 mm (4-1/2 in) - 508 mm (20 in)

- Height: 114 mm (4-1/2 in) - 610 mm (24 in).

- Expansive case range:

- Robust Design

- Built to handle large runs of uniform cases with Leeson, IRON MAN Bottom belt drive system.

Features and Benefits:

- Performance

- Operator-friendly plug-in operation.

- Continuous belt drive speed of 24.4 meters (80 feet) per minute.

- Versatility

- Compact footprint.

- Expansive case range.

- Quick changeover.

- Converts from 51 mm - 76 mm (2" to 3") tape in the field.

- Easy slide and lock height adjustment.

- Width adjustment has self-centering, interlocked guide rails with a steel lock knob.

- Durability

- Ideal for 24/7 operations.

- Powerful 1/3 HP high-efficiency motor drive system.

- 7 gauge steel mast & stainless steel side rails.

- 12 gauge welded steel head and structural platform.

- Safety

- Single mast design allows operator clear path to machine.

- Tape cartridge features patented locking knife guard.

Upgrade your packaging process affordably and efficiently with the LD-7 Case Sealer – the perfect solution for reliable and safe case taping, tailored to meet the needs of your production line.

Brochure

LDX-RTB 4.0 Random Semi-Automatic

Maximizes Productivity

- Performance operating speed of 115 or 155 feet per minute

Simplifies Maintenance

- Easy access to motors, electrical components, and belts for routine maintenance

Production Versatility

- Patented technology enables processing of void-filled and over-stuffed cases with pneumatic tape cartridges

Robust Design

- Case-hardened rollers & non-mechanical side rail actuation for long-term performance & durability

Stainless Steel

- This unit is also available in Stainless Steel. Perfect for food processing operations with a non-tubular design can easily be sanitized to eliminate food borne pathogens.

Standard

All Mechanical Tape Heads

- 115 FPM Conveyor Speed

- Expansive Case Range

- Intuitive Operation

The LDX-RTB Standard semi-automatic random case sealing machine is specifically designed for demanding E-Commerce and Fulfillment applications. It increases efficiency in case packaging lines through its ease of use, expansive case range, and fast throughput speeds. This model comes equipped with two mechanical tape cartridges that can be interchanged between top and bottom. A modular design with easily removable side panels provides access to motors, belts, electrics, and pneumatics for easy service, limiting downtime.

Deluxe

Process Under-Filled Cases

- 155 FPM Conveyor Speed

- Top Pneumatic Tape Cartridge

- Most Popular Model

The LDX-RTB Deluxe semi-automatic random case sealing machine includes all the features of the Standard model, along with a pneumatic-actuated upper tape cartridge for processing high levels of void and compressible overstuffed cases. The belt speed of 155 FPM, coupled with the top pneumatic tape cartridges, ensures high-speed processing of the most challenging cases, maximizing throughput and uptime. Pair the Deluxe with an in-line case former to create a complete packing station.

Premium

High Speed Case Processing

- 155 FPM Conveyor Speed

- Top & Bottom Pneumatic Tape Cartridges

- Bypass Case Feature

E-commerce Production

- 155 FPM Conveyor Speed

- NTRL (OSHA) Certified

- Increased Risk Reduction

LD-16AE Fully Auto Random

The LD-16AE Fully Automatic Random Case Sealer gives you the speed and flexibility you need for efficient case sealing. This machine seals the top and bottom of the case without the use of an operator, automatically adjusting to the case height and width. Utilizing photo eyes to detect box height and a servo-driven linear actuator to lower the tape head, the LD-16AE offers unparalleled flexibility, allowing for up to 9 programmable height positions. Additional heights can be programmed depending on application, making it an ideal choice for egg producers and other industries requiring frequent box size changes and high throughput.

Key Features:

- Maximizes Productivity

- Seals the top and bottom of a case without the need for an operator.

- Technology Driven

- Photo eye sensors and a linear actuator determine random box sizes.

- Production Versatility

- Up to 9 programmable height positions are available.

- Custom Design

- Each machine is designed to seal your specific box range.

Features and Benefits:

- Self-Centering and Self-Tensioning Drive Belts

- Ensures consistent and reliable case sealing.

- High Precision Laser Photo-Eyes

- Detects case height and length accurately.

- 24.4 Meter/Min (80 Feet/Min) Belt Speed

- Provides fast and efficient case processing.

- Top Squeezers and Indexing Gate

- Ensures secure case sealing and alignment.

- Multi-Height Top Head Assembly

- Offers versatility for various case sizes.

- Adjustable Conveyor Height

- 56.5 cm (22.25 in) adjustable up to 72 cm (28.25 in).

- Removable & Interchangeable Tape Cartridges

- Simplifies maintenance and reduces downtime.

- Dual Mast Construction

- High-quality steel structure with powder coat finish ensures durability.

- Stepper Driven, Ball Screw Linear Actuator

- Provides precise control and flexibility in case sealing.

Upgrade your case sealing process with the LD-16AE Fully Automatic Random Case Sealer – the perfect solution for reliable, efficient, and flexible case sealing tailored to meet the demands of your production line.

LD-Xss RTE Uniform Semi-Automatic

Designed for food processing operations, the LDXss RTE features a non-tubular, stainless steel design that can be easily sanitized to eliminate food-borne pathogens. Changes in sanitation standards and new regulations within the food industry have led to the newest design of our stainless equipment. The heavy-duty stainless steel construction, fast/easy maintenance, easy clean non-tubular design, and versatility make this piece of equipment an ideal sealing solution, especially for food processing operations that require special precautions to eliminate bacteria and other food-borne pathogens.

Key Features:

- Heavy Duty Stainless Steel Construction

- Ensures durability and longevity in demanding food processing environments.

- Open, Non-Tubular Design

- Facilitates easy cleaning and sanitization, preventing bacterial growth.

- Patent Pending Quick Release Drive Belts

- Allows for rapid maintenance and minimal downtime.

- Easy Access Motor Mounts for Fast Changeover

- Simplifies the maintenance process and improves efficiency.

- Angled Surfaces for Water Shedding

- Designed to prevent bacterial growth by maximizing water runoff.

- Minimal Overlapping Joints

- Provides full access for thorough cleaning.

- No Hollow Tubular Components

- Eliminates potential contamination points.

- Field Changeover Capability (2” to 3”)

- Offers flexibility for different production needs.

- Mirror Image Changeover

- Enhances operational versatility.

Washdown Design:

- Stainless Steel Construction

- Non-hollow tubular components that prevent bacterial harboring.

- Simplifies Maintenance

- Quick release drive belts and quick disconnect electric cabling for easy washdown.

Production Versatility:

- Ready-to-Eat or Cooked Food Processing

- Specifically designed for operations requiring stringent sanitary conditions.

Washdown Electronics:

- NEMA 4 Electrical Box and NEMA 4X Drive Motor

- Standard features ensuring protection against harsh washdown conditions.

Upgrade your food processing operations with the LDXss RTE Case Sealer – the perfect solution for reliable and sanitary case sealing, tailored to meet the rigorous demands of the food industry.

Case Formers

CF50-T

The CF-50T is a high-performance case sealing machine that automates the formation, folding, and bottom sealing of various corrugated cases. It's versatile, handling everything from double wall to recycled material, and can process up to an impressive 20 cases per minute.

Key Features:

- Efficient 150-load on-the-fly case capacity, with an optional 300-case capacity upgrade accessible from both sides of the machine.

- Chain and lug drive system ensures precise case squaring and accommodates variations in corrugated dimensions.

- Equipped with an Allen-Bradley Micro 820 PLC featuring Ethernet connectivity, sensor functionality, jam detection, and a handy photo eye for detecting box backups.

- User-friendly Eaton HMI provides machine diagnostics, warnings, an Ethernet port, case setup instructions, storage for up to 10 case size parameters, and bilingual support (English/Spanish).

- Chain-driven powered hopper ensures reliable case feeding, eliminating the risk of misfeeds associated with gravity hoppers.

- Boasts a powerful 1/3 HP motor for exceptional efficiency.

- UL listed 508A enclosed panel certification guarantees safety and reliability.

- Fully guarded with a magnetic interlocking safety gate, preventing access to moving parts and automatically shutting off air and electric when gates are opened.

- Complies with the NFPA 79 Electrical Standard, offering comprehensive protection against fire and electrical hazards.

- Seals cases of the shortest length and lowest height with precision.

- Customize your machine with a choice of 51 mm or 76 mm (2" or 3") tape cartridges.

- Self-tensioning chain drive system reduces maintenance and saves time by eliminating the need for adjustments common in side-belt drives.

Elevate your packaging process with the CF-50T from Loveshaw – the ultimate solution for reliable, efficient, and safe case sealing.

CF-5

The CF-5 is a semi-automatic case former capable of handling a variety of case sizes. It has an intuitive design that adjusts to most conveyor heights using slide and lock legs, making it easily compatible with most sealers. The CF-5 uses an Allen Bradley Micro 800 PLC (Programmable Logic Controller) to drive the cases, ensuring precise and reliable operation. This equipment can be easily operated and requires minimal operator training, making it a great addition to any packaging line.

Key Features:

- Increase Productivity

- This semi-automatic case former and pack station can increase output by as much as 40% over hand sealing.

- Minimal Setup

- Only two adjustments needed for a case size changeover.

- Production Versatility

- Attach the CF-5 to a case sealer with optional mounting brackets.

- Intuitive Design

- Adjustable to optimal packing height and mechanically folds bottom flaps of the case.

Features and Benefits:

- Performance

- Allen-Bradley Micro 800 PLC driven - MicroLogix 830 electronically controlled sequencing.

- Ease of programming.

- Versatility

- Expansive case size range with simple box setup and changeover – two adjustment scales.

- Attaches to virtually any case sealer in the industry with optional mounting brackets.

- Simple slide and lock legs, making it easy to match conveyor height.

- User-friendly workplace design.

- Durability

- Heavy-duty steel construction, powder-coated steel frame with stainless steel covers and contact points for wear and corrosion resistance.

- 25 kg (55 lb.) case capability.

Upgrade your packaging process affordably and efficiently with the CF-5 Semi-Automatic Case Former and Pack Station – the perfect solution for reliable and efficient case forming and packing, tailored to meet the needs of your production line.

CF-25

The CF-25 industrial grade, high-performance carton erector is designed to form and bottom-seal corrugated cases at speeds up to 15 cases per minute. This machine maximizes productivity with its intuitive changeover feature and compact footprint, making it an efficient and space-saving addition to any production line. The CF-25 ensures superior performance with its chain and lug drive system, guaranteeing that cases are square during sealing and eliminating slipping and stalling commonly seen in side-belt machines.

Key Features:

- Maximizes Productivity

- Erects and bottom seals up to 15 cases per minute.

- Minimal Setup

- Intuitive changeover feature saves time and increases efficiency.

- Compact Footprint

- Case flow technology allows for in-line, compact footprint.

- Superior Performance

- Chain and lug drive system ensures the case is square during sealing and eliminates slipping and stalling seen in side-belt machines.

Features and Benefits:

- Performance

- Patented case flow technology allows for in-line, compact footprint.

- Reliable case transfer system with upgraded vacuum system and 3 opposing vacuum cups to guarantee all cases, even square cases, open.

- Chain and lug drive system automatically squares cases and compensates for poor tolerances in corrugated dimensions by pushing cases forward.

- Allen-Bradley Micro 820 PLC features Ethernet connectivity, sensor functionality, jam detection, and a photo eye that will detect box backup in the case sealer.

- Eaton HMI features machine diagnostics and warnings, an Ethernet port, case setup instructions, the ability to store up to 10 case size setup parameters, and dual languages (English/Spanish).

- Chain-driven powered hopper positively drives the cases toward the extraction point versus a gravity hopper which can miss feed.

- Powerful 1/3 HP motor for high efficiency.

- Versatility

- 150 load on-the-fly case capacity, accessible from either side of the machine.

- Simple and efficient tool-less case changeover.

- Self-tensioning chain drive system reduces maintenance and time by removing an adjustment point necessary in side-belt drives.

- Durability

- Ideal for 24/7 operations.

- Constructed of 10 and 12 gauge steel with solid 4 post nested construction.

- Linear bearings and hardened sprockets.

- Sealed, maintenance-free gearboxes.

- Safety

- UL listed 508A enclosed panel certification.

- Fully guarded locking safety gate restricts access to moving parts. When gates are opened, air and electric are shut off.

Upgrade your packaging process with the CF-25 Industrial Grade High-Performance Carton Erector – the perfect solution for reliable and efficient case forming and sealing, tailored to meet the demands of your production line.